preserve your product

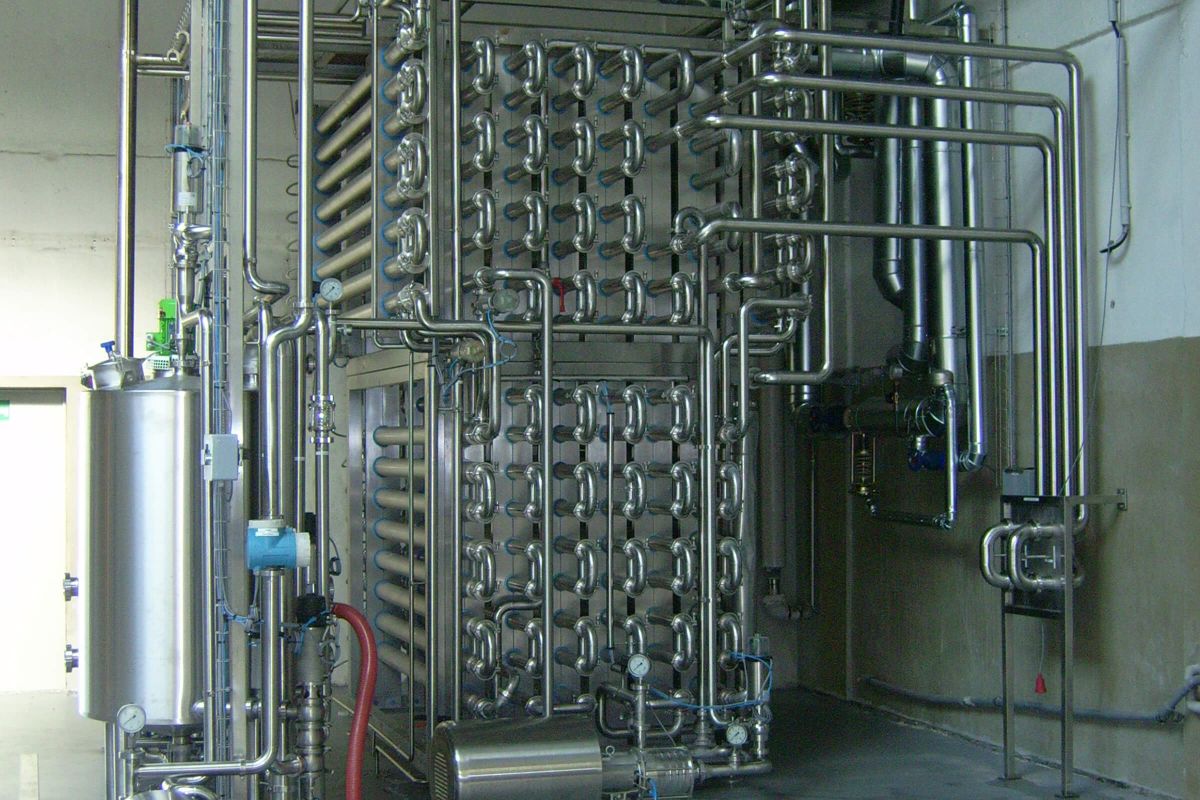

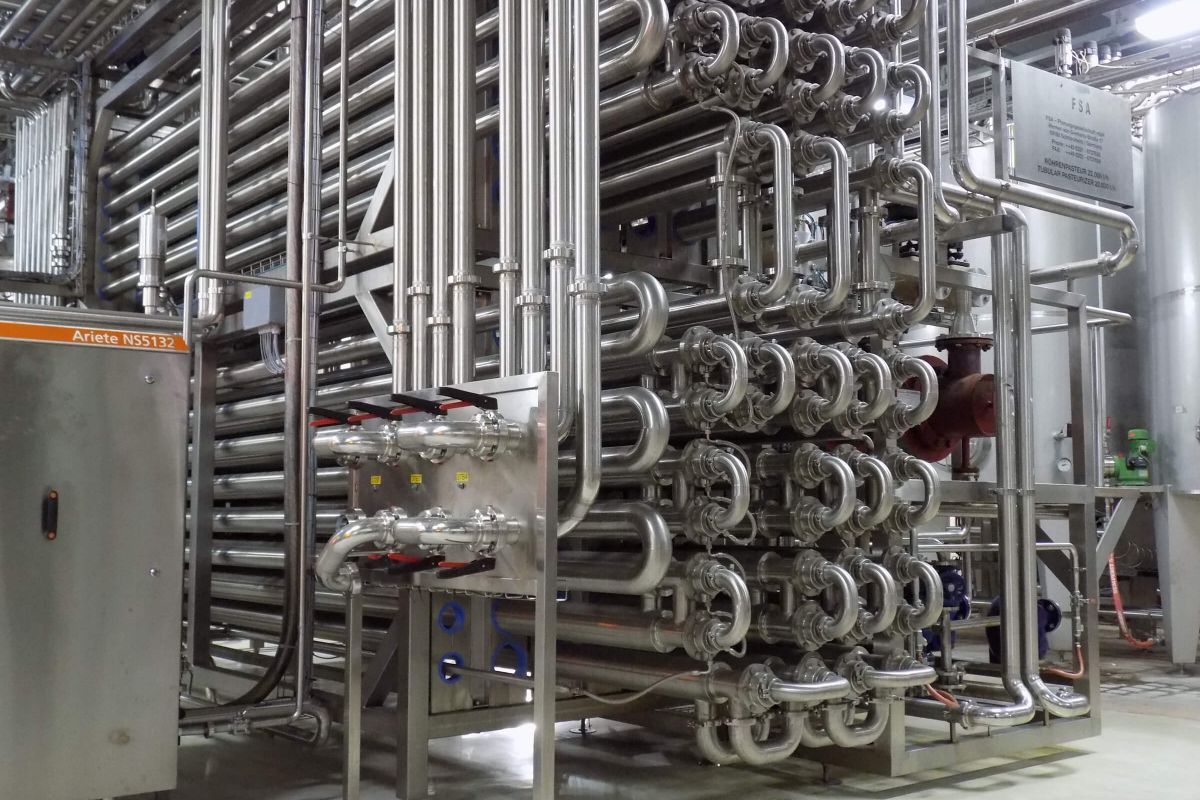

FSA Tubular Pasteurization Systems

FSA Pasteurization systems are used to preserve products in the high-acid range. The technology based on special tubular heat exchangers is the most reliable method of pasteurizing beverages according to the current state of the art.

FSA Pasteurization systems can be used universally and can be combined with all type of filling systems, i.e. all types of aseptic carton packs, hot-fill processes or aseptic PET bottles are possible.

Our advantage and what you can expect from a FSA Pasteurization System:

- Absolute sterility of the products

- Assurance of product quality

- Energy savings

- Pasteurization of products with fibers, dices and high viscosity products

All FSA Pasteurizers can be extended with an FSA Vacuum deaeration systems to achieve further advantages:

- Residual oxygen content in the product below 0.3 ppm

- Reliable product quality thanks to two-stage flavor recovery

- No plug formation during hot filling (when hot-filling fruit juices into bottles, the use of a vacuum deaeration system is essential in order to prevent the formation of plugs and thus the floating of fruit pulp into the bottle neck).